Manufacturing

Unleashing Manufacturing Excellence Through Data Analytics Solutions

Industry 4.0 thrives on digital transformation, leveraging Big Data, IoT, cloud computing, analytics, and artificial intelligence to accelerate decision-making and process optimization. To succeed in this journey, you need a trusted partner that can provide customized solutions to your unique needs.

Realize Industry 4.0’s Potential with QX Impact

QX Impact stands as your ally throughout your transformational journey, crafting strategies that resonate with your business objectives and swiftly executing plans, helping you outperform the competition by equipping you with timely, data-driven insights.

Empower Business Users

Empower your business users with self-service dashboards, granting them quick and easy access to critical data. This not only streamlines decision-making but also frees up valuable time for driving business growth and innovation, rather than spending precious hours on data extraction and analysis.

Gain 360-degree View of Operations

By seamlessly integrating your ERP, MRP, CRM, MES, and other systems into a secure data lake, you’ll gain a comprehensive view of your operations, enabling you to make informed decisions and enhance overall efficiency. Seamless assimilation of IoT data streams into your analytics ecosystem enhances predictive maintenance and real-time monitoring capabilities.

Optimize Manufacturing Operations

Our expertise in advanced analytics and machine learning allows you to predict outcomes and create data-driven operational plans. This ensures that your manufacturing processes run at their peak performance while minimizing inefficiencies, improving productivity, and achieving operational excellence.

Mitigate Risk

Take control of your supply chain by proactively managing risks. Our tailored measures and strategies help you identify, assess, and mitigate potential disruptions, ensuring a smoother and more resilient supply chain that can adapt to unforeseen challenges, safeguarding your operations and reputation.

Migrate Data to Cloud

Ensure adaptability to Industry 4.0 with our cloud migration expertise. We help manufacturing companies migrate data from on-premises systems to platforms like AWS and Azure for scalability and resilience. By designing and implementing an adaptable architecture, future-proof your manufacturing endeavors, enabling you to remain agile and responsive.

Manufacturing Analytics– Sample Use Cases

Predictive Maintenance

Use IoT sensor data to forecast equipment failures, allowing for timely repairs and minimized downtime

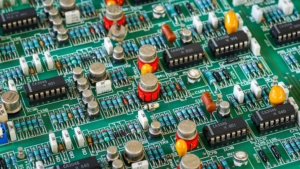

Quality Control and Defect Detection

Identify defects and quality issues in real-time, ensuring product quality and reducing waste.

Production Scheduling

Optimize production scheduling for improved resource utilization and on-time delivery.

Root Cause Analysis

Investigate and address production issues by identifying their root causes through data analysis, reducing recurring problems.

Customer Demand Analysis

Analyze customer data to understand demand trends and tailor production accordingly.

Supply Chain Optimization

Enhance supply chain management, improving demand forecasting, inventory control, and logistics efficiency.

Energy Efficiency

Monitor and analyze energy consumption data to identify opportunities for reducing energy costs and environmental impact.

Asset Performance

Monitor and analyze equipment performance data to extend the lifespan of machinery and reduce maintenance costs.

Labor Force Management

Optimize workforce scheduling, training, and performance assessment using data analytics to enhance labor efficiency.

Inventory Management

Maintain optimal inventory levels, preventing overstock or stockouts, and reducing holding costs.

Manufacturing Analytics– Resources

Explore our collection of resources on manufacturing analytics designed to provide you with valuable insights and strategies.

Ready to transform your manufacturing operations?

Contact us today for a personalized consultation and discover how our analytics solutions can propel your business forward.

FAQ

Commonly Asked Questions on Manufacturing

Data analytics plays a crucial role in the manufacturing industry by providing insights into production processes, identifying inefficiencies, and improving overall efficiency and productivity. By analyzing data from various sources, manufacturers can optimize their processes, reduce waste, and improve product quality. The use of data analytics can also help manufacturers to predict maintenance needs, reduce downtime, and improve supply chain management.

Data analytics is highly beneficial in numerous specific areas within manufacturing:

- Predictive Maintenance: Predictive maintenance utilizes data analytics to continuously monitor the condition of machinery and equipment. By analyzing data patterns, it can forecast when maintenance is needed, thus reducing unplanned downtime, extending equipment lifespan, and minimizing maintenance costs.

- Quality Control: Data analytics helps in real-time monitoring of product quality by identifying defects and anomalies in the production process. This early detection allows manufacturers to make immediate adjustments, ensuring consistent high-quality products and minimizing production costs.

- Supply Chain Optimization: Data analytics is invaluable for optimizing supply chain operations. It provides insights into demand forecasting, inventory management, and logistics, ultimately leading to a more efficient and cost-effective supply chain.

- Energy Management: Data analytics aids in monitoring energy consumption patterns, identifying inefficiencies, and implementing energy-saving measures. This results in reduced energy costs, a smaller environmental footprint, and alignment with sustainability objectives.

- Process Improvement: Data analytics is used to analyze production processes to identify inefficiencies, bottlenecks, and opportunities for improvement. It guides process optimization efforts, leading to increased efficiency and cost savings.

Predictive maintenance utilizes a combination of sensors and data analytics to continuously monitor the condition of equipment and machinery in real-time. It collects data on factors like temperature, vibration, and other relevant parameters. This data is analyzed to identify patterns and anomalies, which are used to predict when equipment is likely to fail. Predictive maintenance benefits manufacturing by reducing unplanned downtime, extending the lifespan of critical equipment, and minimizing maintenance costs. By addressing maintenance needs proactively, manufacturers can ensure a more stable and efficient production process, ultimately leading to increased productivity and cost savings.

Data analytics is a powerful tool for improving product quality. It involves the collection and analysis of data at various stages of the production process to identify trends and anomalies. By closely monitoring the data, manufacturers can detect defects and issues early, enabling them to make necessary adjustments to the manufacturing process. This, in turn, results in a consistent and higher product quality. Beyond enhancing product quality, data analytics also reduces production costs and contributes to higher customer satisfaction, which is crucial for building brand reputation and customer loyalty.

Case Studies and Customer Stories

Discover how our data strategies have brought tangible results to our clients. From optimizing operations to boosting revenue, see real success stories.